Summary

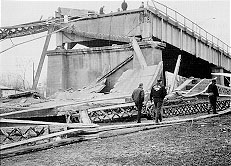

The Silver Bridge was an eyebar-chain suspension bridge built in 1928 which carried U.S. Route 35 over the Ohio River, connecting Point Pleasant, West Virginia, and Gallipolis, Ohio. Officially named the Point Pleasant Bridge,[1] it was popularly known as the Silver Bridge for the color of its aluminum paint.

Silver Bridge | |

|---|---|

The Silver Bridge upon completion in 1928 | |

| Coordinates | 38°50′42″N 82°08′28″W / 38.84500°N 82.14111°W |

| Crossed | Ohio River |

| Locale | Point Pleasant, Mason County, West Virginia, United States Kanauga, Gallia County, Ohio, United States |

| Official name | Point Pleasant Bridge[1] |

| Followed by | Silver Memorial Bridge |

| Characteristics | |

| Design | suspension bridge |

| Material | Steel |

| Total length | 2,235 feet (681 m) |

| Longest span | 700 feet (210 m) |

| Piers in water | 2 |

| Design life | 39 years (until collapse) |

| History | |

| Designer | J. E. Greiner Company[2] |

| Constructed by | American Bridge Company |

| Opened | May 30, 1928[3] |

| Collapsed | December 15, 1967 |

| Location | |

| |

| References | |

| [4] | |

On December 15, 1967, the Silver Bridge collapsed amid heavy rush-hour traffic, resulting in the deaths of 46 people, two of whom were never found. Investigation of the wreckage soon pointed to the failure of a single eyebar in one of the suspension chains as the primary cause — a finding noted in a preliminary report released within 10 months of the collapse.[5] However, to explain why that eyebar failed — a failure triggered by a flaw just 0.1 inches (2.5 mm) deep, which led to a fracture — required significantly more time and effort to uncover, with the final accident report[6] taking three years to complete. The collapse led to significant changes in the way bridges in the U.S. are inspected and maintained.

The collapsed bridge was replaced by the Silver Memorial Bridge, which was completed in 1969.

History of eyebar-chain bridge construction edit

At the time of the Silver Bridge construction, eyebar bridges had been built for about 100 years. Such bridges had usually been constructed from redundant bar links, using rows of four to six bars, sometimes using several such chains in parallel. An example can be seen in the Clifton Suspension Bridge, designed by Isambard Kingdom Brunel having chain eyebars that are redundant in two dimensions; this early suspension bridge is still in service. Other bridges of similar design include the earlier road bridge over the Menai Strait built by Thomas Telford in 1826; the Széchenyi Chain Bridge in Budapest, built in 1839–1849, destroyed in the closing days of World War II by retreating Germans in 1945, and rebuilt identically by 1949, with redundant chains and hangers; and the Three Sisters, three self-anchored suspension bridges in Pittsburgh of similar design and construction period (from 1924 to 1928), each with suspension chains consisting of at least eight eyebars per link.[7]

Silver Bridge structure edit

Low redundancy, high strength edit

The eyebars in the Silver Bridge offered little to no redundancy, as each chain link consisted of just two eyebars in parallel. (Each bar was 45–55 feet long and 2 inches thick;[8] bars were joined together at the eyeholes using cylindrical pins 11.5 inches in diameter.[9]) These eyebars were made of a new, higher-strength steel (more than twice the tensile strength of other steels of that era), which meant fewer eyebars per link were needed to achieve the required strength to support the bridge (earlier such bridges often used four or more eyebars per link). However, with only two eyebars per link, the failure of one of them would hugely increase the loading on the other, making failure of a suspension chain — and the collapse of the entire bridge — far more likely. Accident investigators found that "[h]ad there been three or more eyebars per link, there would have been the possibility that the failure of one bar would not have led to disaster."[6]: 123

By comparison, the Brooklyn Bridge used suspension cables made up of thousands of individual wires each to provide the cables a relatively high safety factor of six. Such a cable also has an extremely high level of redundancy, with the failure of a single wire having almost no effect on its overall strength. During the Brooklyn Bridge's construction, it was discovered that some substandard steel wire had been installed in the cables. To compensate, 150 more good steel wires were added to each cable, supplementing each's 5,434 wires. The designer's son, Washington Roebling, decided the safety factor may have been reduced, but remained more than sufficient.[10][11]

Rocker towers edit

The two towers that supported the two suspension chains rose nearly 131 feet (40 m) from the bridge's main piers. They featured a "rocker" design, which allowed them to tilt slightly at their bases in response to unbalanced loading on the bridge, or to changes in chain length due to temperature change.[12] Prior to their use on the Silver Bridge, rocker towers had been used on a similar bridge in Brazil and, before that, on two large bridges in Europe. Although the rocker towers required the bridge's suspension chains to keep them upright, their ability to tilt allowed the towers to minimize bending stresses — which standard, fixed-base towers must be designed to resist — resulting in a simpler tower design that used less material than fixed towers, and cost significantly less to build.[13]

Early into the collapse investigation, the rocker towers provided a significant clue as to the failure's cause and location. Investigators noticed that both towers had fallen during the collapse, a strong indication that a suspension chain had broken — since neither tower could stand upright without the support of intact chains. (The towers themselves showed no sign of failure.) And the fact that both fell eastward (toward the West Virginia side) clearly indicated a chain break occurring somewhere west of the tower on the western side (i.e., Ohio side) of the bridge. (By contrast, a chain break occurring, say, in the center part of the span would have resulted in the towers falling in opposite directions, away from each other.)[6]: 16

Design loads edit

The bridge, which was designed in 1926–27,[6]: 114 generally conformed to the engineering standards of its era, according to the investigation into the bridge's collapse, and the investigation's review of the original stress calculations underlying the design found no significant errors.[6]: 15 A few years earlier, in 1923, AASHO, a national standards-setting organization, had released documentation to aid engineers in designing bridges — providing quality-control specifications and guidelines on topics such as computing forces and loads, types and properties of steel, and estimating future traffic levels.[6]: 115–117

The bridge's eyebars, which used a new, stronger steel, offered a maximum allowable stress of 50,000 psi, significantly higher than most other steels then in use, and the bridge had a design safety factor of 1.50, within engineering norms.[6]: 118 Investigators into the collapse found no indication that the bridge had been overloaded, even on the day it failed. Despite the bridge's age and the heavy traffic on it at the time of its collapse, the load it was carrying was found to be within its normal capacity;[8] and the location where the failure occurred was at less than half the maximum "live" load it was designed to handle when the collapse began.[6]: 98

Wreckage analysis edit

The bridge failure was due to a defect in a single link, known as eyebar 330, on the north of the Ohio subsidiary chain, the first link below the top of the Ohio tower. A small crack was formed through fretting wear at the bearing, and grew through internal corrosion, a problem known as stress corrosion cracking. The crack was only about 0.1 inches (2.5 mm) deep when the link failed, breaking in a brittle fashion.[14]

When the lower side of the eyebar failed, all the load was transferred to the other side of the eyebar, which then failed by ductile overload. The joint was then held together only by three eyebars, and another slipped off the pin at the center of the bearing, so the chain was completely severed. A collapse of the entire structure was inevitable since all parts of a suspension bridge are in equilibrium with one another.

The damage to the link would have been difficult to see during inspection of the bridge:

Inspection prior to construction would not have been able to notice the tiny crack ... the only way to detect the fracture would have been to disassemble the eye-bar. The technology used for inspection at the time was not capable of detecting such cracks.[15]

Aftermath edit

The collapse focused much-needed attention on the condition of older bridges, leading to intensified inspection protocols and numerous eventual replacements. There were only two bridges built to a similar design, one upstream at St. Marys, West Virginia, and the notably longer Hercílio Luz Bridge at Florianópolis, Brazil. The St. Marys bridge was immediately closed to traffic and was demolished by the state in 1971. (A small truss bridge remained to allow access to an island in the river.) The Hi Carpenter Memorial Bridge was later built to replace the demolished bridge.

The Hercílio Luz Bridge remained in active service until 1991. Although both it and the Silver Bridge used the same type of high-strength steel for the eyebars,[6]: 84 it was built to a higher safety factor than the West Virginia bridge and had greater redundancy, with each suspension chain using an array of four eyebars per link,[16] compared to just two per link for the Silver Bridge.[6]: 123 But in 1991, the Florianópolis bridge was closed due to high levels of corrosion. Following extensive renovation, it reopened in December 2019.

Modern non-destructive testing methods allow some of the older bridges to remain in service, but with tighter weight restrictions. Most heavily used bridges of this type have been replaced with bridges of more modern design.

The collapse inspired legislation to ensure that older bridges were regularly inspected and maintained; however, aging infrastructure is still a problem in the United States. In 1983, the Mianus River Bridge in Greenwich, Connecticut, collapsed, causing the deaths of three drivers. In 2007, the I-35W Mississippi River bridge disaster in Minneapolis, Minnesota, resulted in 13 deaths. In early September 2009, the failure of an eyebar in the San Francisco–Oakland Bay Bridge was discovered during a scheduled closure, resulting in an emergency repair to reinforce the failed member.

A memorial was installed in Point Pleasant to commemorate the 46 bridge-collapse victims.

A scale model of the original Silver Bridge was on display at the Point Pleasant River Museum. An archive of literature about the bridge was also kept there for public inspection. On the lower ground floor, the museum displayed an eyebar assembly from the original bridge. The museum closed on July 1, 2018, due to significant fire damage. The future of the Silver Bridge exhibit is not known.[17]

Another eyebar example has been erected for public viewing at a small rest area on the Ohio side of the river, along Route 7.

The bridge has been designated as a National Historic Civil Engineering Landmark by the American Society of Civil Engineers as its collapse ultimately led to the creation of the first national bridge inspection program in the Federal-Aid Highway Act of 1968.[18]

Legacy edit

Reviewing the collapse and subsequent investigation in his 2012 book To Forgive Design: Understanding Failure, engineering historian Henry Petroski finds it "a cautionary tale for engineers of every kind." As a result of the thoroughness of the investigation, the cause of the disaster was precisely and indisputably found to be "a design that inadvertently made inspection all but impossible and failure all but inevitable. If ever a design was to blame for a failure, this was it."[19]

Petroski does not fault the bridge's designers, who were unaware of many of these hazards. Instead, he points to the future. "If there is anything positive about the Silver Bridge failure," he concludes, "it is that its legacy should be to remind engineers to proceed always with the utmost caution, ever mindful of the possible existence of unknown unknowns and the potential consequences of even the smallest design decisions."[19]

In popular culture edit

In his 1970 book Operation Trojan Horse, and in his 1975 book The Mothman Prophecies, Fortean author John Keel linked the Silver Bridge collapse to alleged sightings of the Mothman. The story was adapted as a film by the same name, released in 2002.[20]

Author Jack Matthews wrote a novella, Beyond the Bridge, written as the diary of an imaginary survivor of the disaster starting a new life as a dishwasher in a tiny West Virginia town.

Honky tonk singer-songwriter and West Virginia native Ray Anderson released "The Silver Bridge Disaster" as the A-side of a 1967 single.

Silver Memorial Bridge edit

Silver Memorial Bridge | |

|---|---|

| Coordinates | 38°50′04″N 82°08′51″W / 38.83444°N 82.14750°W |

| Carries | 4 lanes of US 35 |

| Crosses | Ohio River |

| Locale | Gallipolis, Ohio to Henderson, West Virginia |

| Maintained by | West Virginia Department of Transportation |

| Characteristics | |

| Design | cantilever bridge |

| Total length | 1,964 feet (599 m)[21] |

| Width | 60 feet (18 m)[21] |

| Longest span | 900 feet (270 m) |

| Clearance below | 69 feet (21 m)[21] |

| History | |

| Opened | December 15, 1969[22] |

| Location | |

The Silver Memorial Bridge is a cantilever bridge that spans the Ohio River between Gallipolis, Ohio, and Henderson, West Virginia. The bridge was completed in 1969 as a replacement for the collapsed Silver Bridge, although it is located about 1 mile (1.6 km) downstream (south) of the original.[23]

The bridge carries US 35 across the river and serves as a major crossing for people and goods traveling between Charleston, West Virginia, and Southern and Central Ohio. The speed limit on the bridge is 65 mph (105 km/h). No toll is imposed at either end.

See also edit

References edit

- ^ a b Witcher, T.R. (December 2017). "From Disaster to Prevention: The Silver Bridge". Civil Engineering Magazine. 87 (11). American Society of Civil Engineers: 45. doi:10.1061/ciegag.0001250. Retrieved 6 November 2023.

- ^ Witcher, T. R. (December 2017). "From Disaster to Prevention: The Silver Bridge" (PDF). Civil Engineering. Reston, Va.: American Society of Civil Engineers. Archived from the original (PDF) on 2018-01-05. Retrieved 2018-01-04.

- ^ "Silver Bridge". transportation.wv.gov. Retrieved 2018-12-24.

- ^ Silver Bridge at Structurae. Retrieved 2018-01-04.

- ^ Passaglia, Elio (1999). "The Investigation of the Point Pleasant Bridge Collapse". NIST Digital Archives. National Institute of Standards and Technology. Retrieved 4 November 2023.

Excerpt of 'A Unique Institution: The National Bureau of Standards, 1950–1969,' by Elio Passaglia, NIST Special Publication 925.

- ^ a b c d e f g h i j "Highway Accident Report: Collapse of U.S. 35 Highway Bridge, Point Pleasant, West Virginia, December 15, 1967" (PDF). NTSB.gov. National Transportation Safety Board. 16 December 1970. Retrieved 2 November 2023.

- ^ Griggs, Frank Jr. (April 2022). "Silver Bridge Failure (aka Point Pleasant Bridge)" (PDF). StructureMag.org. Structure magazine. p. 62. Retrieved 2 November 2023.

- ^ a b "Point Pleasant Bridge Collapse". NIST Digital Archives. National Bureau of Standards. August 1971. p. 196. Retrieved 4 November 2023.

- ^ Passaglia, Elio (1999). "The Investigation of the Point Pleasant Bridge Collapse". NIST Digital Archives. National Institute of Standards and Technology. p. 577. Retrieved 4 November 2023.

Excerpt of 'A Unique Institution: The National Bureau of Standards, 1950–1969,' by Elio Passaglia, NIST Special Publication 925.

- ^ Talbot, Jim (June 2011). "The Brooklyn Bridge: First Steel-Wire Suspension Bridge" (PDF). Modern Steel Construction. Chicago: American Institute of Steel Construction. Retrieved 2018-01-04.

- ^ Oviatt-Lawrence, Alice (May 2019). "The Brooklyn Bridge Masonry ~1860–2019". StructureMag.org. Structure magazine. Retrieved 4 November 2023.

- ^ Ballard, Wilson T. (20 June 1929). "An Eyebar Suspension Span for the Ohio River". Internet Archive. Engineering News-Record. p. 998. Retrieved 29 November 2023.

- ^ Steinman, D.B. (13 November 1924). "Design of the Florianopolis Suspension Bridge". Internet Archive. Engineering News-Record. p. 781. Retrieved 29 November 2023.

- ^ https://archive.org/details/sim_american-society-of-civil-engineers-collected-journals_1993-11_119_4/page/220/mode/2up?q=silver+bridge+collapse, pp.249-261

- ^ LeRose, Chris (October 2001). "The Collapse of the Silver Bridge". West Virginia Historical Society Quarterly. 15 (4).

- ^ "Large Eyebar Suspension Bridge in South America". Internet Archive. Engineering News-Record. 11 October 1923. p. 592. Retrieved 28 November 2023.

- ^ Steelhammer, Rick (July 28, 2018). "Point Pleasant River Museum director details fire, plans to rebuild". Charleston Gazette-Mail. Retrieved 2018-09-20.

- ^ Sergent, Beth (December 27, 2019). "Silver Bridge named as a National Historic Civil Engineering Landmark". Gallipolis Daily Tribune. Retrieved 2021-11-26.

- ^ a b Petroski, Henry (2012). To Forgive Design: Understanding Failure. Cambridge, Massachusetts: Harvard University Press. p. 174. ISBN 9780674065840.

- ^ De Vos, Gail Arlene (2012). What Happens Next?: Contemporary Urban Legends and Popular Culture. ABC-CLIO. pp. 89ff. ISBN 978-1598846348.

- ^ a b c "National Bridge Inventory: Structure 00000000027A063". Retrieved 2008-11-24.[permanent dead link]

- ^ Cahal, Sherman. "Sherman Cahal: Silver Memorial Bridge (US 35)". Retrieved 2008-11-24.

- ^ [1][dead link]

Further reading edit

- Seim, Charles (May 2008). "Why Bridges Have Failed Throughout History". Civil Engineering. 78 (5): 64–71, 84–87.

- Bullard, Stephan; et al. (2012). The Silver Bridge Disaster of 1967. Charleston, S.C.: Arcadia Publishing. p. 128. ISBN 978-07385-9278-7.

External links edit

- Silver Memorial Bridge at Bridges & Tunnels.

- West Virginia Division of Culture and History "On This Day" provides a link to the official state disaster video the next day, archive 1.6 MB wmv file having good quality, no sound: http://www.wvculture.org/history/av/silverbridge256.wmv

- Bridge collapse video to show sequence of events

- Case study of bridge collapse

- Video concerning collapse includes comparison of Silver Bridge and earlier eyebar chain suspension bridges using lower strength materials

- "The Collapse of the Silver Bridge: National Bureau of Standards Determines Cause" at National Institute of Standards and Technology Virtual Museum