With over 16% contribution to global GDP, the manufacturing industry continues to grow while acknowledging rapid technological advancements. Disruptive technologies such as AI and data analytics combined with IoT are introducing automation to major manufacturing facilities. Under AI development services, applications of computer vision for manufacturing plants extend from quality inspection to inventory management and safety compliance.

This blog post explores effective use cases of computer vision technology across small and large scale production lines.

Quality and Packaging Inspection

Quality control is an essential business principle for every manufacturing organization. However, it is challenging for SMBs to bear the high operational costs and labor associated with quality control measures.

Emerging technologies such as IoT and AI are demonstrating high-end capabilities for automating the traditional quality control practices. Mckinsey’s lab research reveals that AI-powered IoT devices will raise manufacturing productivity and product quality by almost 20%.

The algorithmic advancements in AI’s computer vision technology are entering quality control facilities with more efficient and cost-effective solutions, such as-

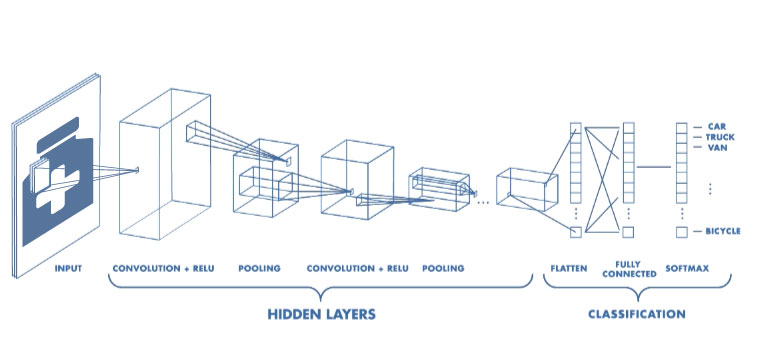

a) Analyzing visual imagery with convolutional neural networks (CNN), a regularized version of multilayer perceptrons, that enable accurate identification of defected products.

A look at the hidden layers of a CNN model.

b) Automation in packaging has opened the path for computer vision algorithms to supervise the standard quantity and methodology over packaging lines.

c) Automated defect inspection using pattern matching algorithms is replacing manual labor at electronics part manufacturing, medicine, and agricultural yield inspection.

How does Oodles AI use computer vision to automate quality inspection facilities?

We, at Oodles, have working knowledge of computer vision technologies to build real-time video surveillance systems. We use CNN and histogram of oriented gradients (HOG) to automate manufacturing processes in the following manner-

a) Our deep video analytics detect anomalies over production lines and raise an alarm during quality inspection. We have achieved over 80% accuracy in detecting defected products while maintaining speed.

b) After identifying differences, our model automatically saves the images and video frames inside the system for further training purposes. It leads to the comprehensive training of ML models that accelerate production and derive better returns.

Product Assembly and Safety Compliance

Workforce and data security is a major concern for manufacturing businesses. According to the International Labor Organization, over 2.3 million workers die every year due to occupational accidents or work-related diseases.

Computer vision techniques have already automated the inspection of basic product standards such as seal closure, position, labeling, and print quality. The future applications of computer vision techniques to ensure product compliance and workplace safety will witness the following developments-

a) Video Surveillance in-built with image processing techniques will enable businesses to track employee movements and with greater precision and associated data.

b) Optical character recognition (OCR) systems can sift through date codes, lot code, and expiration date to identify differences accurately. Also, OCR is efficient at tracking complete production cycles from raw materials to packaging lines.

c) Also, the integration of artificial intelligence services in sensor-based IoT devices can detect the overheating of machines well before the condition aggravates. Data from powerhouses such as voltage and tension can be used by computer vision techniques to predict short circuits.

Unlocking Computer Vision for Manufacturing Businesses with Oodles AI

The AI team at Oodles uses large machine learning (ML) libraries such as OpenCV and TensorFlow to train ML models. With OCR, real-time video analysis, object detection, and other computer vision techniques, we ensure safety for manufacturing in the following ways-

a) Our computer vision capabilities are efficient at mapping real-time employee and product positions to identify anomalies.

b) We use OCR systems to monitor complex product operations and details such as batch number, manufacturing details, expiration date, and more.

Talk to our AI development team to know more about our Computer Vision Services.